TM 5-4310-354-14

semble disc holder (13) on stem (16).

around the spindle (30) and body (34), at

Assemble stem (16) into valve body (17),

connection of nipple (24) and body (34),

assemble bonnet (12) over stem (16) and

and connection of nipple (24) and valve

install union nut (11). Assemble packing

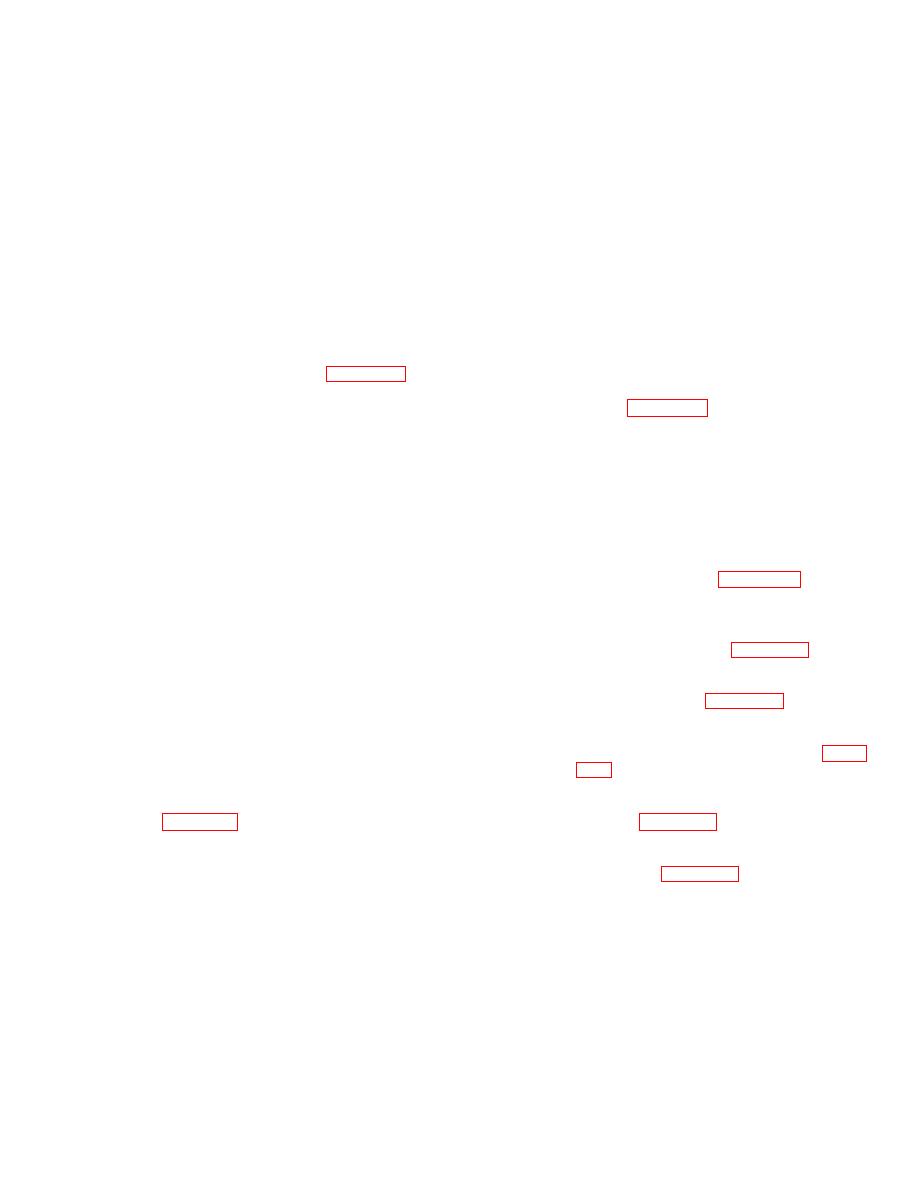

(4). Check valve (4) for leaking. Leakage

(10), packing gland (9), and packing nut

check can be accomplished by applying a

(8).

Place

handwheel

(7)

and

soapy water solution applied with a brush

identification plate (6) on stem (16) and

to these connections. Leakage will be

secure with nut (5). Assemble the angle

indicated by bubbling of the solution.

valve (4) onto nipple (24), install two street

elbows (3, 2) in angle valve (4). Install

(3) If leakage occurs, the hose reel must be

hose end (1) in street elbow (2).

disassembled,

cleaned,

inspected,

repaired, reassembled, and retested.

f. Testing. After hose reel is reassembled, test for

Relieve the test pressure and remove the

leaks as follows:

hose reel assembly from the test air

source.

(1) Close the angle valve (4, figure 4-11) by

turning handwheel clockwise.

Attach

g. Installation. Install the hose reel assembly by

spindle (30) to an air source capable of

screwing spindle (30, figure 4-11) into discharge opening

producing 100 psi air pressure.

of non return valve assembly on oil separator assembly.

Place one end of air service hose assembly through

(2) Apply this air pressure of 100 psi to the

opening in reel end, connect to hose end (1) on reel,

hose reel assembly. Check for leaking

wind the hose on the reel and lock with braking knob

(25).

Section X. MAINTENANCE OF COMPRESSOR ENCLOSURE GROUP

(2) Remove the charging receptacle from end

and oil cooler assembly, and instrument panel are

panel as shown in figure 4-10, removal

housed in a sheet metal enclosure. Doors on both sides

step 4 and step 7.

of the unit provide access to these components. In

addition to the doors, the enclosure consists of an end

(3) Remove the quick start assembly from

cover access panel, end panel, exhaust deflector, and

end panel as shown in figure 4-13.

roof section. The data and instruction plates attach to

the outside of the enclosure.

(4) Remove the engine overspeed shutdown

switch as shown in figure 4-14.

4-27. Compressor Enclosure.

(5) Remove the engine and compressor air

a. Removal and Disassembly.

cleaner assemblies as shown in figure

(1) Remove the exterior components to gain

access to compressor enclosure as shown

(6) Remove the data and instruction plates as

in figure 4-12.

shown in figure 4-16.

(7) Disconnect the two oil separator hose

assemblies (figure 4-22, step 1).

4-30