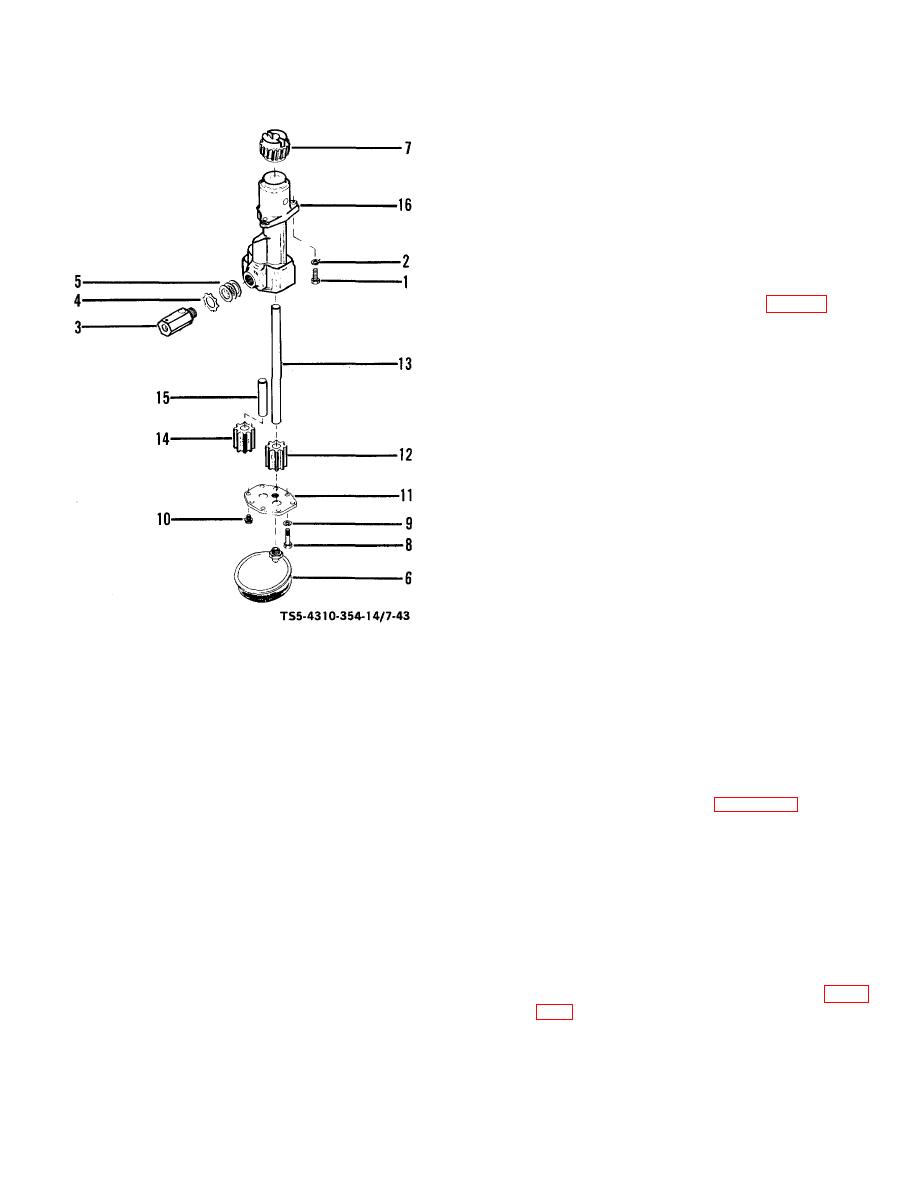

TM 5-4310-354-14

(c) Remove drive impeller (12) and shaft (13)

as an assembly.

If necessary, press

impeller (12) off shaft (13).

(d) Remove impeller (14) from shaft (15).

Shaft (15) is a press fit into body (16).

Pull the shaft (15) from body (16) only

when necessary.

b. Cleaning, Inspection, and Repair.

(1) Clean all parts in accordance with para 5-7. f.

(2) Inspect the oil pump strainer (6) for clogged

screen, holes, damaged threads, dents, or other

damage. Make sure the oil passage is clear and

unobstructed. Replace a damaged or distorted

strainer.

(3) Inspect all gears (7, 12, 14) for worn or broken

teeth; replace if damaged.

(4) Inspect all parts for burrs, pitting, rust, scoring,

cracks, breaks, and damaged threads. Replace

any damaged parts.

(5) Replace idler shaft (15) if shaft has turned in

pump body (16) or is worn smaller than 0.6220

inch (15.7988 mm) diameter at gear bearing

area.

TS 5-4310-354-14/7-29

(6) Replace drive shaft (13) if shaft has turned in

1.

Cap screw (2)

9.

Lock washer (2)

gears or is worn smaller than 0.6220 inch

2.

Lock washer (2)

10.

Screw assy (6)

(15.7988 mm) diameter at bearing points.

3.

Regulator

11.

Cover

4.

Lock washer

12.

Drive impeller

(7) Check piston for binding in regulator body;

5.

Shims (AR)

13.

Drive shaft

replace regulator (3) if piston binds.

6.

Strainer

14.

Idler impeller

7.

Drive gear

15.

Idler shaft

c. Reassembly.

8.

Cap screw (2)

16.

Pump body

(1) Press drive impeller (12, figure 7-43) onto the

Figure 7-43. Oil pump assembly, disassembly and

drive shaft (13) so that the outside face of the

reassembly.

impeller and the end of the shaft are flush.

Once removed, do not press old parts back

(a) Remove the strainer (6) from cover (11).

together.

Bend up tangs of lock washer (4) and

remove regulator (3), lock washer (4), and

(2) Insert the shaft and impeller a sembly into the

s

shims (5). Do not disassemble regulator

pump body (16). Press the drive gear (7) onto

(3).

the shaft (12).

Replace gear that can be

pressed onto the shaft with less than 35 pounds

(b) Use a gear puller to remove drive gear (7)

(15.876 kg) gauge pressure. Press the gear

from shaft (13). Remove the two cap

onto the shaft to the dimensions shown in figure

screws (8) and lock washers (9), six screw

assemblies (10). and cover (11).

7-49