TM 5-4310-354-14

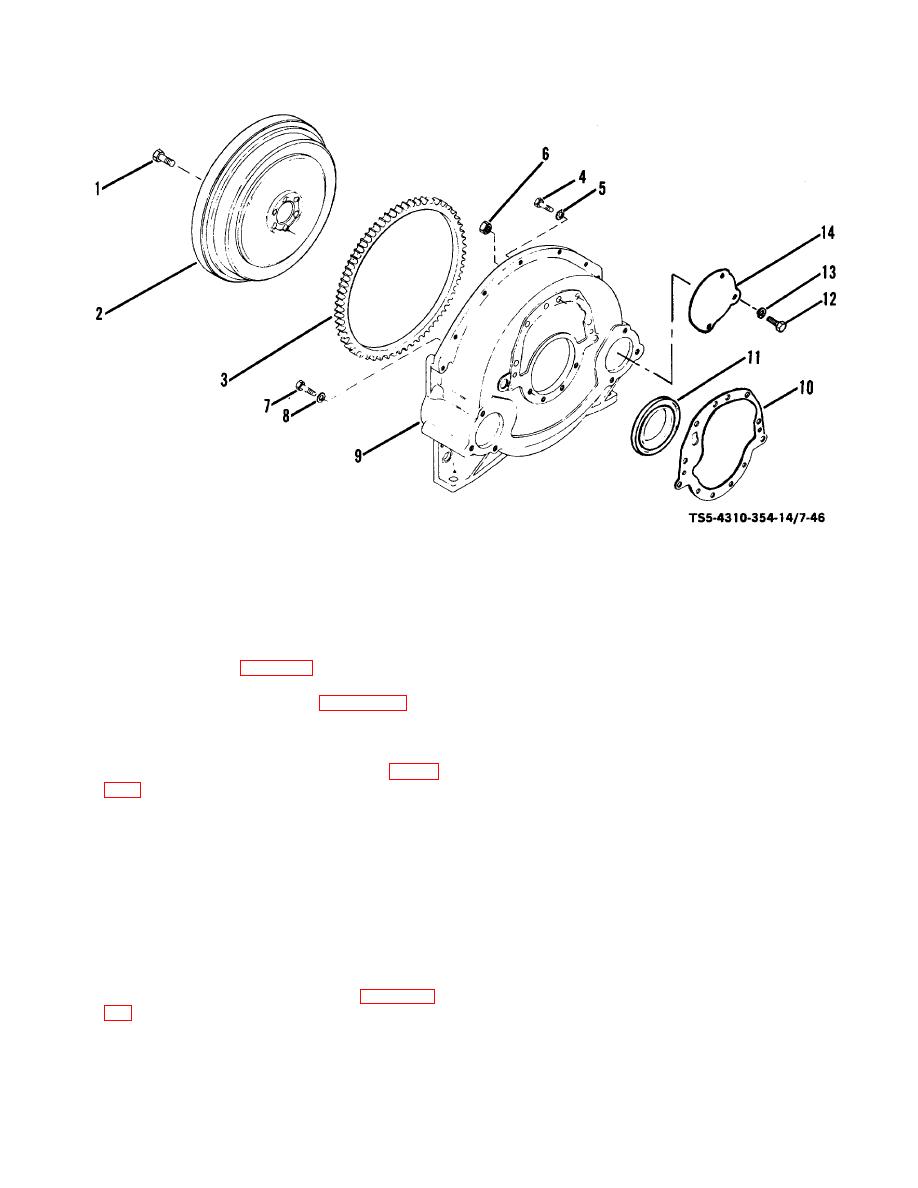

1.

Flywheel cap screw (6)

8.

Washer (4)

2.

Flywheel

9.

Bellhousing

3.

Ring gear

10.

Gasket

4.

Cap screw (6)

11.

Seal

5.

Lock washer (8)

12.

Cap screw (3)

6.

Nut (2)

13.

Lock washer (3)

TS 5-4310-354-14/7-46

7.

Cap screw (4)

14.

Cover

Figure 7-46. Flywheel and bellhousing, disassembly and reassembly.

(4) Do not attempt to remove ring gear (3) from

(2) Inspect the flywheel ring gear (3) for brok en or

flywheel (2) unless it is damaged and must be

cracked teeth.

If damage is evident and

replaced.

replacement is necessary, drive the gear (3)

from flywheel (2) with a blunt chisel.

(5) Remove the oil pan (para 7-15).

(3) Inspect the flywheel (2) for distortion, cracks, or

(6) Remove rear oil pan adapter (figure 7-41) by

other damage or wear. Replace a damaged

first removing two nuts and lock washers

flywheel.

securing adapter to cylinder block studs; then,

remove four cap screws and lock washers

(4) To install a new ring gear (3), heat it in an oven

securing adapter to the bellhousing (9, figure

or with a heating torch to approximately 600F

(315.6C). Do not overheat. Place heated ring

gear on flywheel (2) and quickly drive onto

(7) Remove cap screws (4, 7), washers (5, 8) and

flywheel until gear is firmly seated.

nuts (6). Separate bellhousing (9) from cylinder

block and remove gasket (10).

(5) Discard and replace gasket (10) and oil seal

(11). Make sure all gasket material is removed

(8) Press seal (11) out of bellhousing (9). Remove

from mating surfaces.

cap screws (12), lock washers (13), and cover

(14) from bellhousing (9).

(6) Inspect the bellhousing (9) for cracks, distortion,

and other damage; replace a damaged

b. Cleaning, Inspection, and Repair.

bellhousing.

(1) Clean all parts in accordance with paragraph

(7) Check that bellhousing dowel pins in the block

5-7.f.

are tight and in good condition.

7-52