TM 5-4310-354-14

c. Reassembly and Installation.

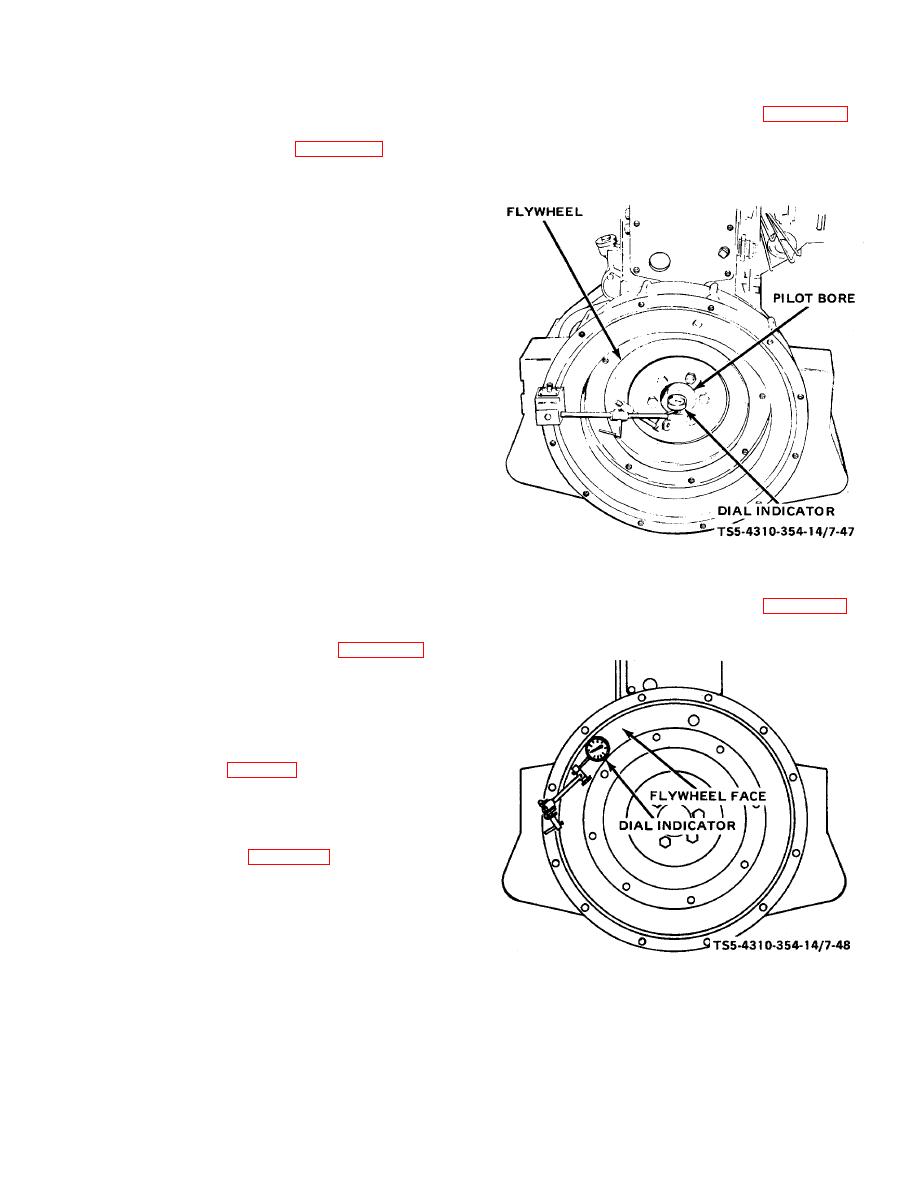

(8) Attach an indicator, as shown in figure 7-47, to

check the concentricity of the pilot bore. This

(1) Install a new oil seal (11, figure 7-46) in the

should not exceed 0.005 inch (0.127 mm) total

bellhousing (9), using a small amount of sealing

indicator reading.

compound in the bore before pressing in the

seal.

If new seal is pre-coated, sealing

compound is not required.

Cement a new

gasket (10) to the bellhousing (9), allowing the

cement to dry sufficiently to prevent the gasket

from slipping at installation.

(2) Clean and polish the oil seal surface of the

crankshaft to remove nicks or scratches. Use

crocus cloth or very fine polishing cloth.

(3) Apply a thin coat of oil soap to the seal and the

seal surface of the crankshaft. If seal is already

oil treated, additional lubricant is not required;

however, take care to keep the seal surface

clean during reassembly. Make sure that the

top rear cam thrust plate attaching screw hole is

plugged with a setscrew. This hole runs into an

oil hole in the block.

Carefully place the

bellhousing (9) on the cylinder block so that the

seal is not damaged as it engages the

TS 5-4310-354-14/7-47

crankshaft. Align so that the dowels properly

enter their respective holes.

Seat the

Figure 7-47. Indicating flywheel pilot bore.

bellhousing (9) to the engine and install the cap

screws (4, 7), nuts (6), and lock washers (5, 8)

(9) Attach the indicator, as shown in figure 7-48, to

but do not tighten.

check the face of the flywheel. Runout

(4) Install the rear oil pan adapter (figure 7-41),

securing it to the cylinder block with two nuts

and lock washers. Secure the adapter to the

bellhousing with four bolts and lock washers.

Tighten down the bellhousing cap screws and

nuts evenly and securely.

(5) Install the oil pan (para 7-15).

(6) Turn the crankshaft so that the timing cylinder

(No. 1) is in the top dead center position.

(7) Turn the flywheel (2, figure 7-46) so that the DC

timing mark is in line with the timing hole in the

bellhousing (9). Install the flywheel (2) on the

crankshaft. Note that one of the six cap screws

(1) is off center so that the flywheel (2) can only

be installed in one position. This ensures proper

TS 5-4310-354-14/7-48

location of the flywheel on the crankshaft for

timing purposes. Draw the flywheel onto the

Figure 7-48. Indicating flywheel face.

crankshaft by tightening the six cap screws

alternately and evenly. Torque the bolts to 80

foot-pounds (11.064 kg-m).

7-53