TM 5-4310-354-14

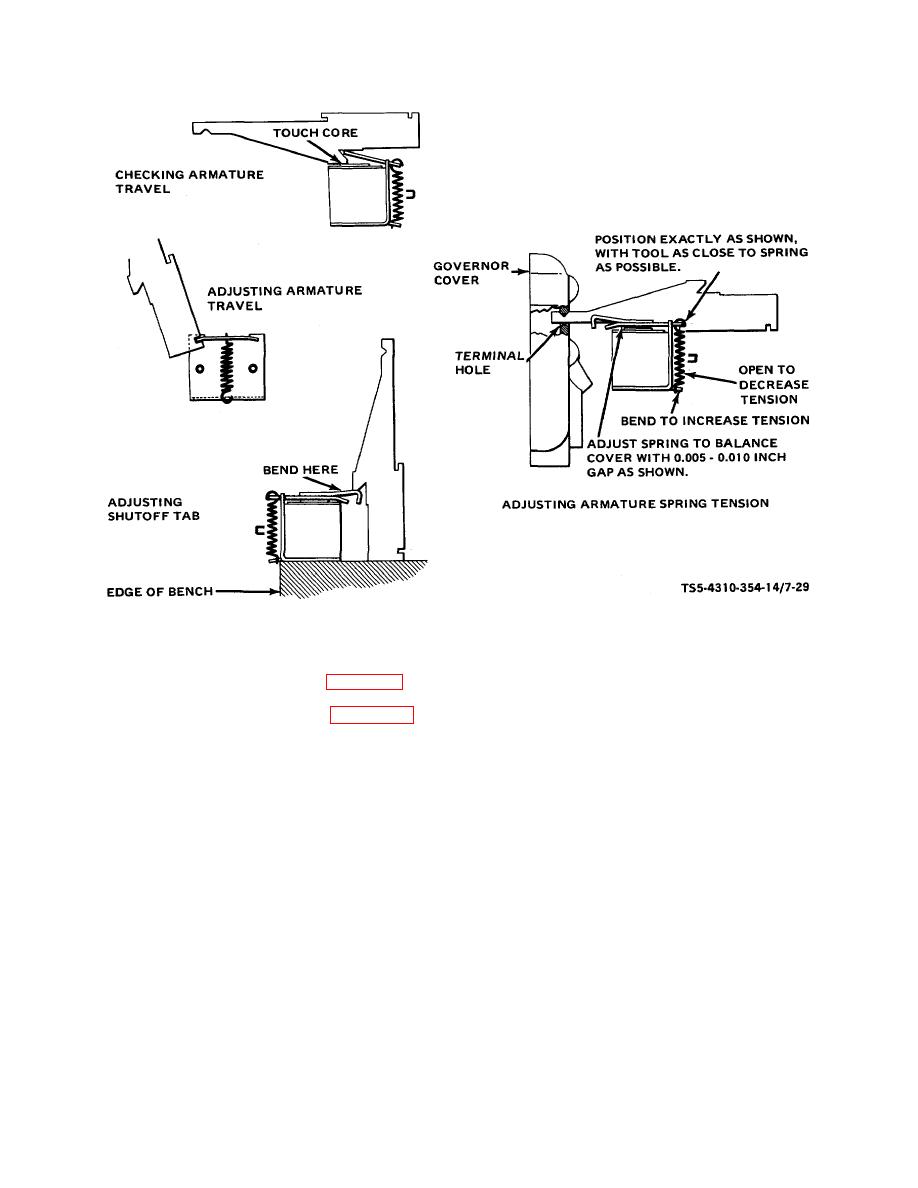

TS 5-4310-354-14/7-29

Figure 7-29. Armature and spring tension adjustment.

(b) Using same tool, adjust shutoff tab and

Assemble the two cover gaskets (118), timing

spring tension as shown in figure 7-29.

covers (117), and secure with screws (116). If

removed from housing, install identification plate

(25) Install new insulating tubes (13, igure 7-16) on

(120) with screws (119).

solenoid studs. Apply light coating of clean

mineral grease to the tubes (13) and assemble

e. Bench Testing.

After overhaul, prior to

solenoid assembly to cover (6).

Assemble

installation on the engine, the fuel injection pump should

insulating washers (11), contact washers (10),

be bench tested as follows:

contact nuts (9), and lock nuts (8) on solenoid

stud terminals. Install fuel return connector (5)

NOTE

into cover (6).

Using a new gasket (7),

assemble the cover assembly (6) to housing

All tests must be conducted using

(121) with three flat washers (4), lock washers

heated calibrating oil. Heat oil to

(3), and screws (2).

After testing and

110-115F (43 -46 C). Use 12SD12

adjustment, install wires and seals (1).

nozzles set to open at 2500 psi

2

(175.75 KG/CM ). Injection lines shall

(26) Assemble fuel line gaskets (110) and fuel line

be 3/32 inch (2.38 mm) inside

screws (109) finger tight until ready to install fuel

diameter, 20 inches (508 mm) long.

injection lines after pump is installed on engine.

Fresh, clean oil is necessary for

accurate testing and should be

changed as often as excessive foam

is noted.

7-30