TM 5-4310-354-14

NOTE

Pump adapters are available for the

following makes of commercial test

benches:

American Bosch, TSE

7664, TSE 4500, TSE 4600; Unitest, U-

4500, U-4600; Bacharach, GP-500C,

SP-600; Hartridge, J,L.NU.

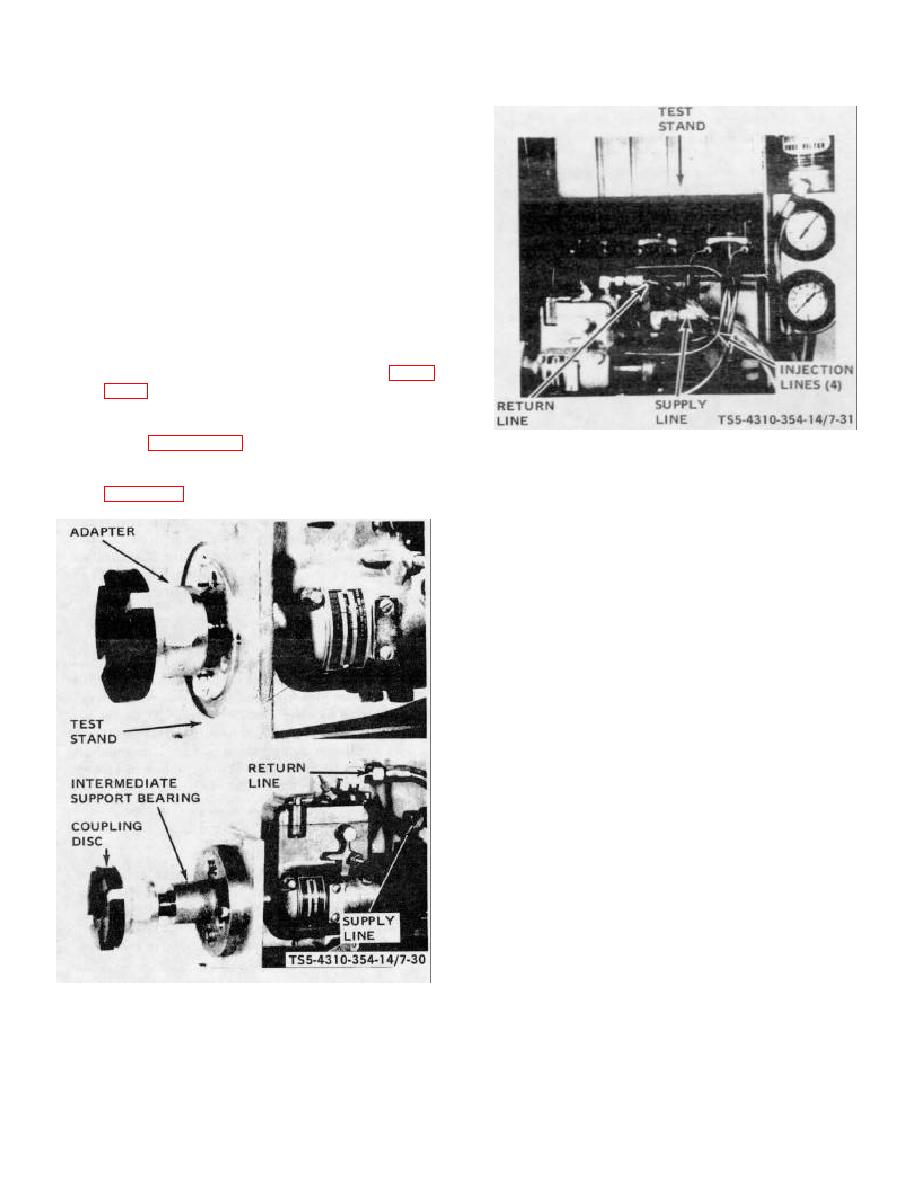

(1) Mount the pump securely on test bench using

the appropriate adapter for bench being

employed. Pumps having bronze pilot tubes

must have shaft supplied with the pump

removed and the pump mounted on the stand

using shaft provided by test stand manufacturer.

(No support bearing is required.) Refer to figure

support the shaft in the housing and must be

TS 5-4310-354-14/7-31

tested using an intermediate support bearing.

(See figure 7-30.) Check the intermediate

Figure 7-31. Fuel line connections, test setup.

coupling disc for freedom of movement.

Connect supply and return lines securely. (See

(2) Install high pressure injection lines using new

copper gaskets. Leave the fuel line connector

screws at the pump and the injection line nuts

and nozzles loose until air is bled from pump

and lines.

NOTE

This pump's rotation direction is

clockwise as viewed from drive end

of pump.

(3) Start the stand at lowest speed. Move pump

throttle to "full load" position. When transfer

pump picks up suction, allow fuel to bleed for

several seconds from the loose connector

screws and from injection line nuts; then, tighten

connector screws and injection line nuts

securely.

(4) Operate the pump at full load rated speed of

2200 rpm for several minutes.

Dry off

completely with solvent and compressed air.

Observe for leaks and correct as necessary.

(5) Close valve in supply line. Transfer pump must

pull minimum of 15 inches Hg. If it does not,

check for air leaks on suction side or malfunction

TS 5-4310-354-14/7-30

of end plate and transfer pump parts.

Figure 7-30. Bench test mounting.

7-31