TM 5-4310-376-14

SERVICING - Continued

3-6.

d. Daily Draining of Air Receiver Tank

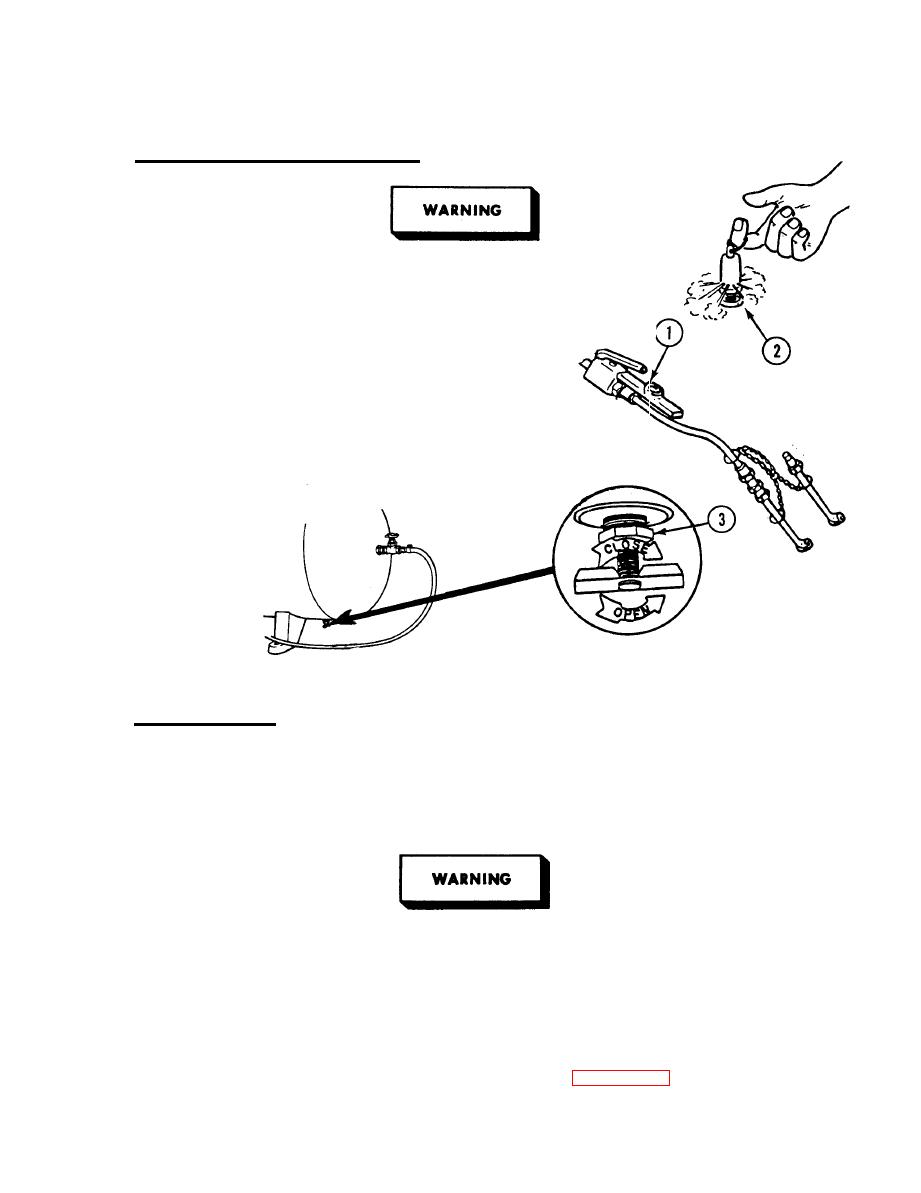

Release air pressure from air compressor before perform-

ing procedures to avoid personnel injury.

(1) To release air pressure, depress inflator gage handle (1) or

pull ring on receiver tank safety valve (2).

(2) Air is drained when hissing sound stops.

(3) Turn air receiver tank drain cock (3) counterclockwise

until it stops.

(4) Water will drain out. When water is no longer draining out

of air receiver tank, turn drain cock clockwise until it is

tight.

3-7. CLEANING AND INSPECTION

a. Compressor Drive

(1) Belt Guard

(a) Inspect for damage to screen, bends, dents, missing hardware and other damage.

(b) Check for accumulation of grease, soaked dust, dirt or other foreign matter.

Dry cleaning solvent P-D-680 (safety or Stoddard's sol-

vent) is potentially dangerous. Avoid repeated and pro-

longed breathing of vapors and skin contact with the

liquid. Do not use near open flame, arcing equipment or

other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100

to 138F (30 to 59C).

(c) Clean with a cloth dipped in cleaning solvent (item 1, Appendix E), then wipe dry.

3-9