TM 5-4310-376-14

CLEANING AND INSPECTION - Continued

3-7.

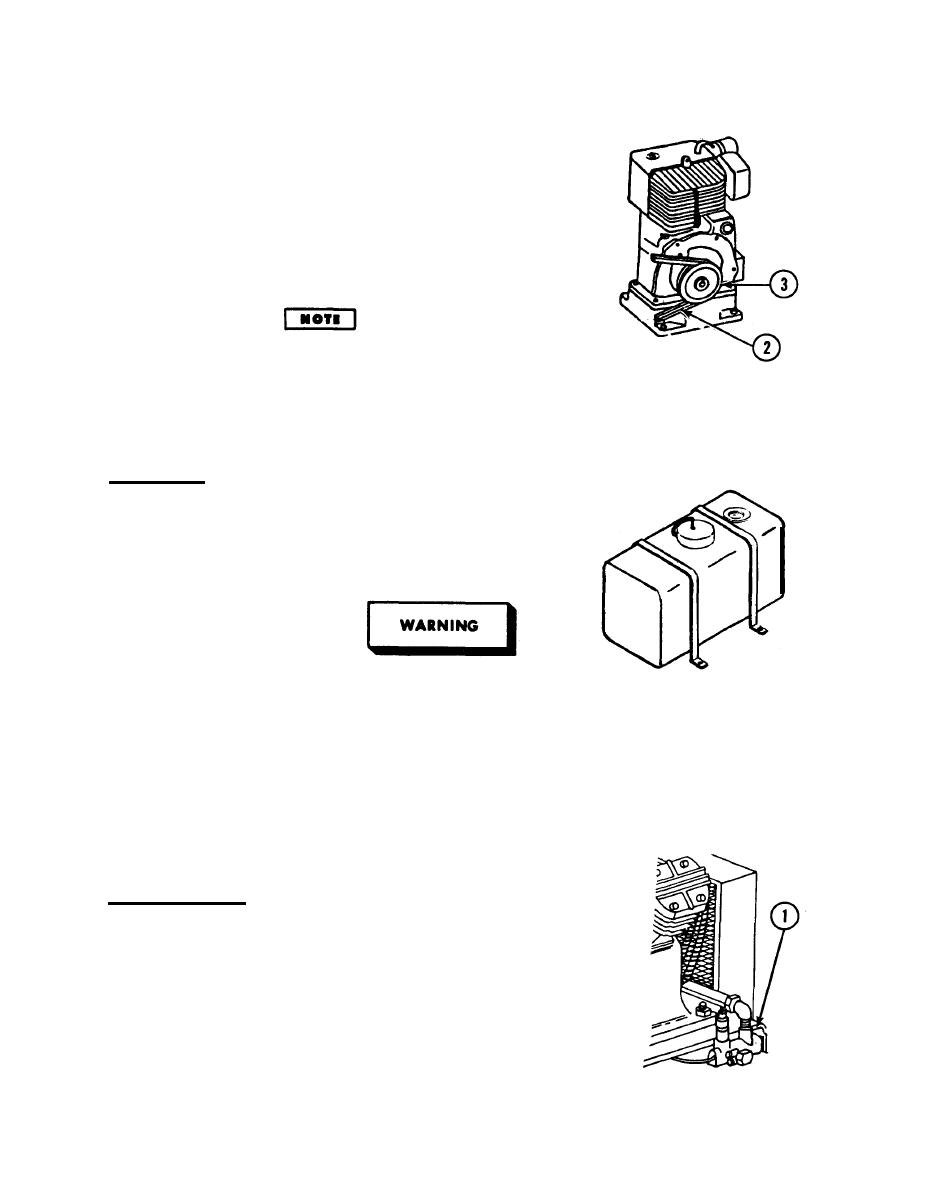

(2) V-Belts (2)

(a) Inspect for cracks, fraying, and excessive wear.

(b) Clean with a clean, dry cloth. Do not use solvent

to clean belt set. If dirt or grease persists, scrub

with soap and water and allow to dry thoroughly.

A quick check for proper adjustment is to

observe belts while compressor is in opera-

tion. If top of belt seems to droop slightly

below line from pulley, belts are in adjust-

ment.

b. Fuel System

(1) Fuel Tank

Inspect for gum, dirt, or foreign material.

(2) Cleaning

Dry cleaning solvent P-D-680 (safety or Stoddard's Sol-

vent) is potentially dangerous. Avoid repeated and pro-

longed breathing of vapors and skin contact with the

liquid. Do not use near open flame, arcing equipment or

other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100

to 138F (30 to 59C).

Clean inside and outside and all applicable parts with an approved cleaning solvent, dry

thoroughly.

c. Capacity Control (1)

(1) Tubing

Inspect for leaks and loose connections.

(2) Valve

Check for proper operation. When air pressure reaches

200 +0, -10 psi, valve opens and air is vented to atmosphere.

3-10