TM 5-4310-376-14

CLEANING AND INSPECTION - Continued

3-7.

Valve will remain open until air pressure in air tank falls

below 175 10 psi.

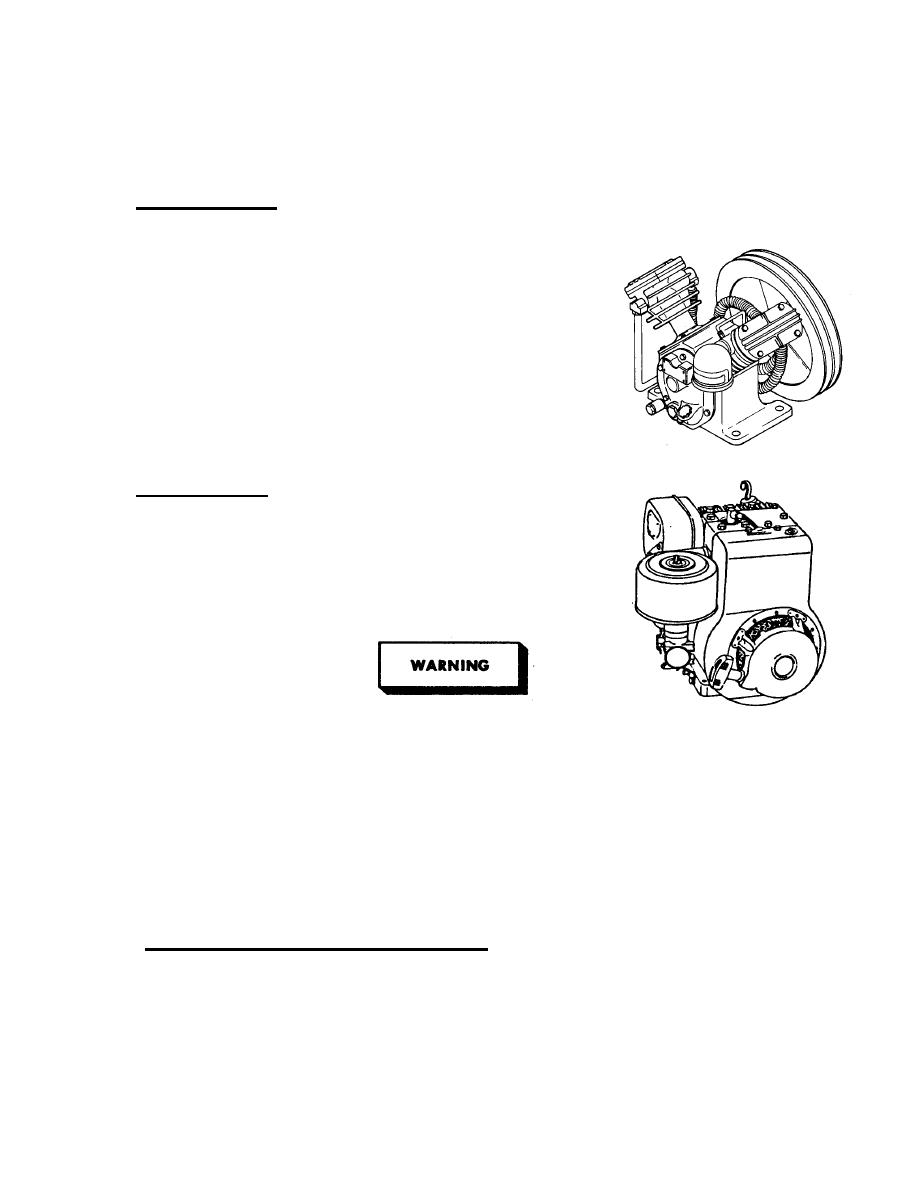

d. Compressor Pump

Kept clean and lubricated, pump should be relatively free

of maintenance.

(1) Inspection

During operation listen carefully for a knock or rattle that

might signify internal damage. Inspect for excessive ac-

cumulation of dust, dirt, or oil film.

(2) Cleaning

Wipe off all oil spots, then dry. Use compressed air to blow

dust or dirt off.

e. Engine Assembly

(1) Inspection

Inspect for cracks, breaks, leaky fuel filter, loose spark plug,

missing hardware, or other damage.

(2) Cleaning

Dry cleaning solvent P-D-680 (safety or Stoddard's Sol-

vent) is potentially dangerous. Avoid repeated and pro-

longed breathing of vapors and skin contact with the

liquid. Do not use near open flame, arcing equipment

or other ignition sources. Always wear eye protection

and protective clothing. The flash point of P-D-680 is

100 to 138F (30 to 59C).

Clean with approved cleaning solvent and dry thoroughly. Use compressed air to blow

dust or dirt off. Clean cooling fins and entire engine.

f. Air Receiver (1) and Discharge Systems (2)

(1) Inspection

Inspect for excessive accumulation of dust, or leaking or spilled oil. Check pressure gage

safety valve, globe valve, drain cock, air hose, and inflator gage for leaks.

(2) Cleaning

3-11