TM 5-4310-376-14

Section II. SERVICE UPON RECEIPT

4-4. UNLOADING AND UNPACKING

a. Inspect the shipping crate for damage that may have been caused during shipment. Report

any damage on DD Form 6, Packaging Improvement Report.

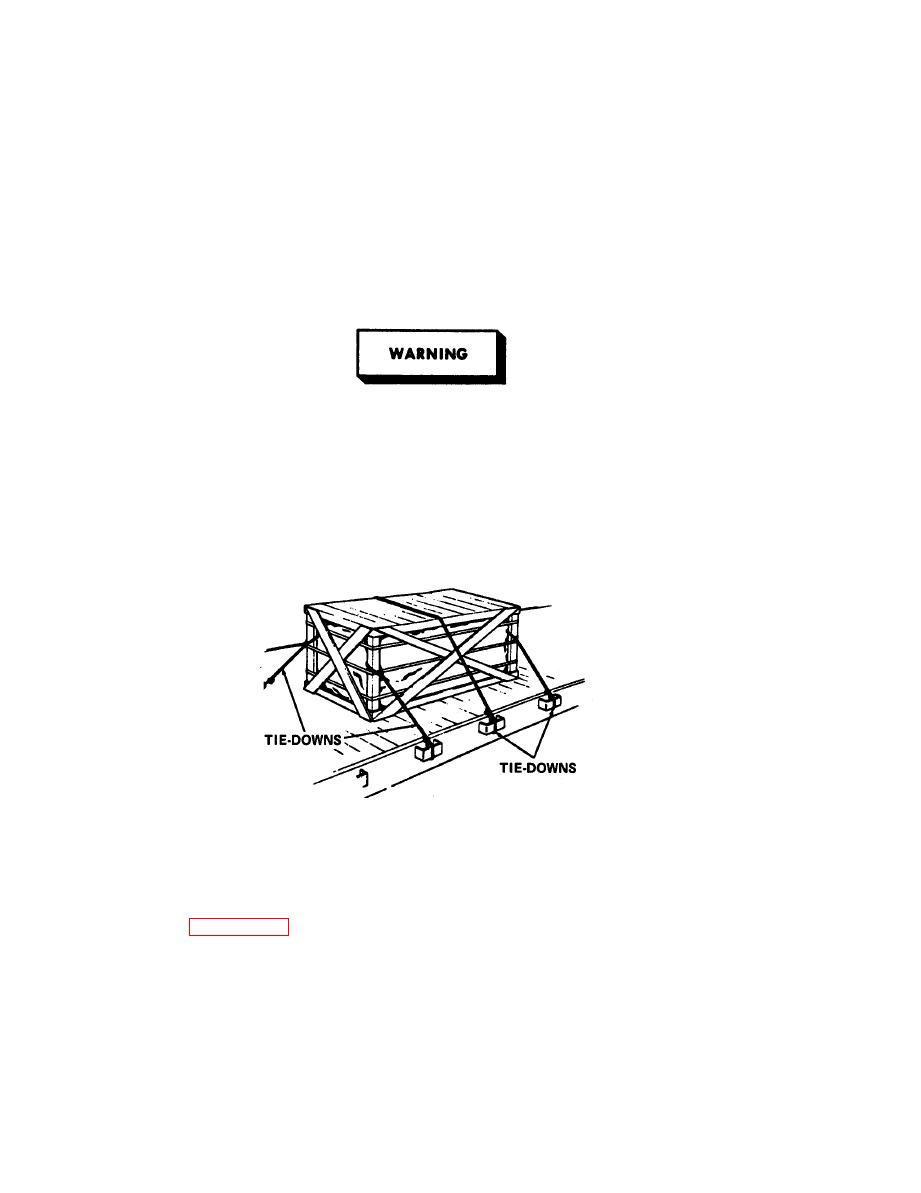

b. Remove all tiedowns or blocking that secure the compressor to the carrier.

c. A forklift truck, or other suitable hoist must be used when removing the crated compressor

from the carrier.

Injury to personnel or damage to equipment could occur

from improper hoisting. Hoist the load slowly to avoid

tearing out lifting eye assemblies, slipping slings or load

shift. Do not jerk the load or swing it from side-to-side

when hoisting. This places additional stress on hoisting

components which can cause failure and loss of load. Be

sure hoisting equipment is on solid footing and is suitable

for the size of the load. Watch boom angle and overhead

clearance when hoisting.

d. Place the air compressor as close to the point of installation as possible.

e . Remove the crate from the base, being careful not to damage the air compressor.

f. Remove box banded to the bottom of the crate. Check contents of the box against t h e

packing list. If packing list is not available, check contents against components of End Item

List (COEIL) in Appendix C of this manual.

g. Remove the four nuts and lockwashers that secure the air compressor to the bottom of

the crate. Using a forklift truck, remove the air compressor.