TM-5-4310-389-14

17.

Turn the crankshaft through 360 degrees int he direction of engine rotation. Undo the cylinder head and remove

the piece of lead wire. Measure the thinnest part of the squeezed wire. For piston crown clearances, see

specifications table 4-2.

NOTE

This is the easiest method of getting the correct clearance; if the clearance is too small, remove the

cylinder and place the number of shims required below the cylinder or if the clearance is too large,

raise the cylinder, cut through the surplus shims with side-cutting pliers, and remove.

18.

Adjust clearance by shims: 0.008-inch (0.2 mm), 0.020-inch (0.5 mm), 0.032-inch (0.8 mm), or 0.039-inch (1.0

mm) are available. Keep the number of shims in the stack to an absolute minimum.

19.

Reinstall the cylinder head. Refer to 4-11 and Appendix F.

20.

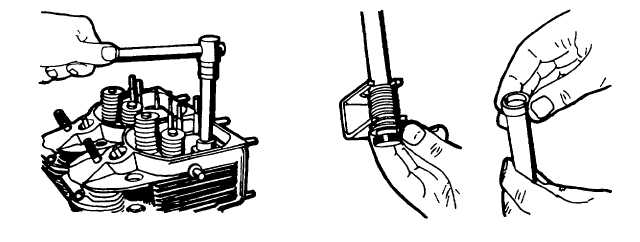

Screw plugs into cylinder heads fitted with new gaskets into the holes for the cylinder head studs (use socket

spanner No.003-0512 and square socket insert No.44 003-0511, figure 5-44).

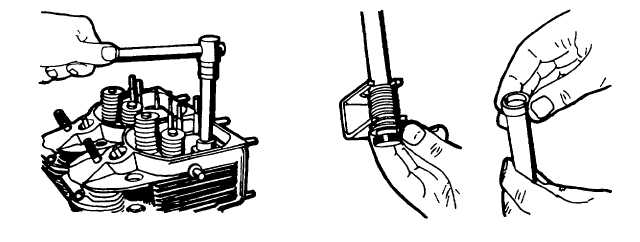

21.

Assemble and tension the spring by turning (use spring compressor tool No. 003-0501, figure 5-45, left).

22.

Install the flat washer with the domed side facing towards the spring. Fit a new sealing ring with the flat side

facing towards the end of the push rod tube (figure 5-45, left).

23.

At the opposite end of the tube, fit a new sealing ring with the fault side facing towards the shoulder (figure 5-45,

right).

Figure 5-44. Fitting Screw Plugs into

Figure 5-45. Assembling Push Rod

Cylinder Head

Assemblies

5-27